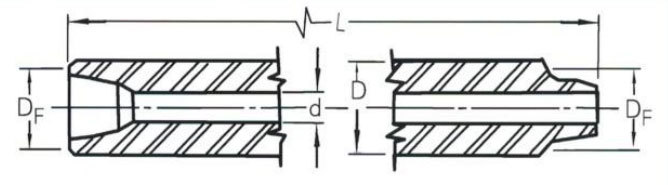

Ordinary drill collar

The drill collar is made of AISI4145H Cr-Mo steel and follows API Specifications and SY/T5144 standards. The threads can be processed with cold rolling, coppering or phosphating. Our company can machine double-shoulder threads and other specifications of special threads. The maximum outer diameter of the drill collar that can be produced by our company is 14 inches.

Key words:

Classification:

Message consultation

Product Details

The Company possesses a complete set of petroleum drilling tool production lines and mainly produces large deep-hole boring machines, ordinary lathes, CNC lathes, mill, printer, etc. The Company has established a dedicated testing center that is equipped with domestic and overseas advanced precision testing equipment and sound testing means to control the whole process of products and strictly abides by API 7-1, API 7-2, SY/T5144 and SY/T5146 standards to ensure that all performance indexes of the Company’s products can meet international standards and standards of American Petroleum Institute (API). The Company has passed IS09001 quality management system certification and HSE management system certification and has obtained the right to use the logos of API petroleum drilling tools. Main drilling tools include non-magnetic drill collar, non-magnetic pressure drill pipe, ordinary drill collar, integrated heavy weight drill pipe, adapter, etc. The annual production capacity is 10,000 pieces. The Company can also machine products according to special requirements of users.

● Standard dimensions, inside diameter and thread

|

ID Connection |

OD |

ID |

mm Length |

Shoulder chamfer diameter mm |

Bending strength ratio |

||

|

mm |

in |

mm |

in |

||||

|

NC23-31 |

794 |

31/8 |

31.8 |

11/4 |

9150 |

76.2 |

2.57:1 |

|

NC26-35 |

88.9 |

31/2 |

38.1 |

11/2 |

9150 |

82.9 |

2.42:1 |

|

NC31-41 |

104.8 |

41/8 |

50.8 |

2 |

9150 or 9450 |

100.4 |

2.43:1 |

|

NC35-47 |

120.7 |

43/4 |

50.8 |

2 |

9150 or 9450 |

114.7 |

2.58:1 |

|

NC38-50 |

127.0 |

5 |

57.2 |

21/4 |

9150 or 9450 |

121.0 |

2.38:1 |

|

NC44-60 |

152.4 |

6 |

57.2 |

21/4 |

9150 or 9450 |

144.5 |

2.49:1 |

|

NC44-60 |

152.4 |

6 |

71.4 |

213/16 |

9150 or 9450 |

144.5 |

2.84:1 |

|

NC44-62 |

158.8 |

61/4 |

57.2 |

21/4 |

9150 or 9450 |

149.2 |

2.91:1 |

|

NC46-62 |

158.8 |

61/4 |

71.4 |

213/16 |

9150 or 9450 |

150.0 |

2.63:1 |

|

NC46-65 |

165.1 |

61/2 |

57.2 |

21/4 |

9150 or 9450 |

154.8 |

2.76:1 |

|

NC46-65 |

165.1 |

61/2 |

71.4 |

213/16 |

9150 or 9450 |

154.8 |

3.05:1 |

|

NC46-67 |

171.4 |

63/4 |

57.2 |

21/4 |

9150 or 9450 |

159.5 |

3.18:1 |

|

NC50-67 |

171.4 |

63/4 |

71.4 |

213/16 |

9150 or 9450 |

159.5 |

2.37:1 |

|

NC50-70 |

177.8 |

7 |

57.2 |

21/4 |

9150 or 9450 |

164.7 |

2.54:1 |

|

NC50-70 |

177.8 |

7 |

71.4 |

213/16 |

9150 or 9450 |

164.7 |

2.73:1 |

|

NC50-72 |

184.2 |

71/4 |

71.4 |

213/16 |

9150 or 9450 |

169.5 |

3.12:1 |

|

NC56-77 |

196.8 |

73/4 |

71.4 |

213/16 |

9150 or 9450 |

185.3 |

2.70:1 |

|

NC56-80 |

203.2 |

8 |

71.4 |

213/16 |

9150 or 9450 |

190.1 |

3.02:1 |

|

65/8REG |

208.6 |

81/4 |

71.4 |

213/16 |

9150 or 9450 |

195.7 |

2.93:1 |

|

NC61-90 |

228.6 |

9 |

71.4 |

213/16 |

9150 or 9450 |

212.7 |

3.17:1 |

|

75/8REG |

241.3 |

91/2 |

76.2 |

3 |

9150 or 9450 |

223.8 |

2.81:1 |

|

NC70-97 |

247.6 |

93/4 |

76.2 |

3 |

9150 or 9450 |

232.6 |

2.57:1 |

|

NC70-100 |

254.0 |

10 |

76.2 |

3 |

9150 or 9450 |

237.3 |

2.81:1 |

|

85/8REG |

279.4 |

11 |

76.2 |

3 |

9150 or |

266.7 |

2.84;1 |

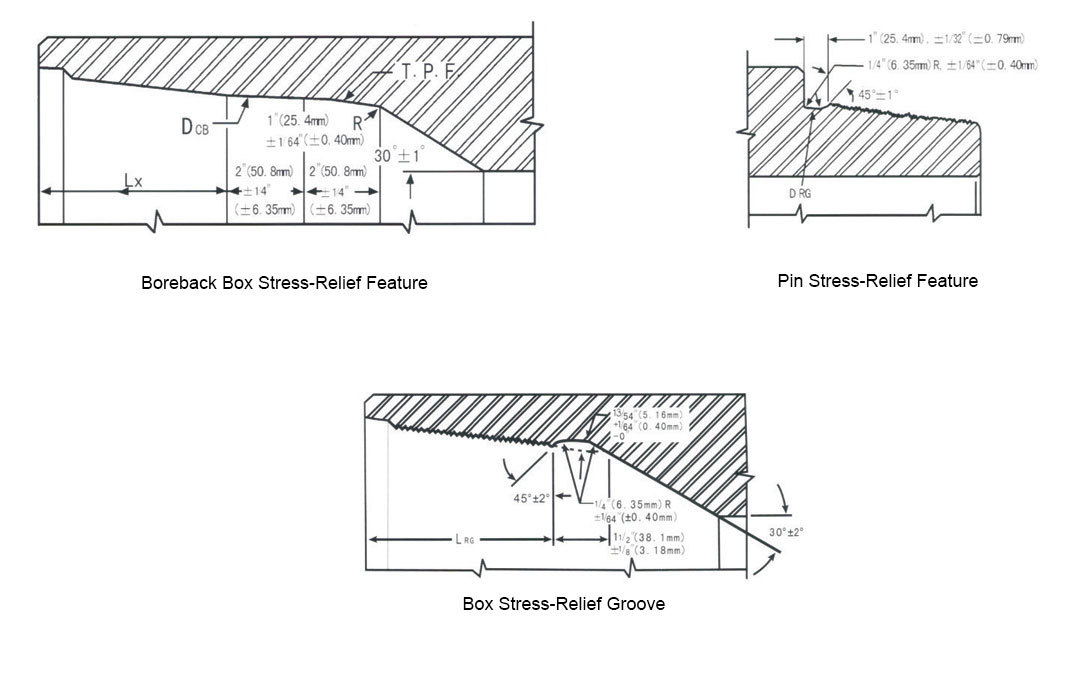

Elevator and Slip Recesses

According to the needs of users, the hanger groove and slip groove structure can be processed on the drill collar to meet the requirements of API specifications.

Drill collar slot and slip slot dimensions

Sizes of elevator and slip recesses

|

Outside diameter of drill collar OD |

Depth of elevator groove LE±0.2 |

R1C |

Angle αb |

Card groove depth LS±0.4 |

Angle βb |

|

101.6-117.5 |

5.6 |

3.2+0.4 |

4° |

4.8 |

3.5° |

|

120.6-142.9 |

6.4 |

3.2+0.4 |

5° |

4.8 |

3.5° |

|

146.0-168.3 |

7.9 |

3.2+0.4 |

6° |

6.4 |

5° |

|

171.4-219.1 |

9.5 |

4.8+0.8 |

7.5° |

6.4 |

5° |

|

≥222.2 |

11.1 |

6.4+0.8 |

9° |

6.4 |

5° |

Mechanical property

| Outer diameter range OD |

σ0.2 |

σb |

δ4 |

Brinell hardness |

AK |

|

|

mm |

in |

|||||

|

79.4~174.6 |

31/8-63/4 |

≥758 |

≥965 |

≥13 |

≥285 |

≥54 |

|

177.8~279.4 |

7~11 |

≥689 |

≥931 |

|||

Main tolerance dimensions of drill collar

| Outer diameter range OD | OD |

ID |

Length | D,Bevel Diameter |

|

|

mm |

in |

||||

|

≤88.9 |

≤31/2 |

+1.2 0 |

+1.6 0 |

+152.4 |

40.4 |

|

>88.9~114.3 |

>31/2~41/2 |

+1.6 0 |

|||

|

>114.3~139.7 |

>41/2~51/2 |

+2.0 0 |

|||

|

>139.7~165.1 |

>51/2~61/2 |

+3.2 0 |

|||

|

>165.1~215.9 |

>61/2~81/2 |

+4.0 0 |

|||

|

>215.9~241.3 |

>81/2~91/2 |

+4.8 0 |

|||

|

>241.3 |

>91/2 |

+6.4 0 |

|||

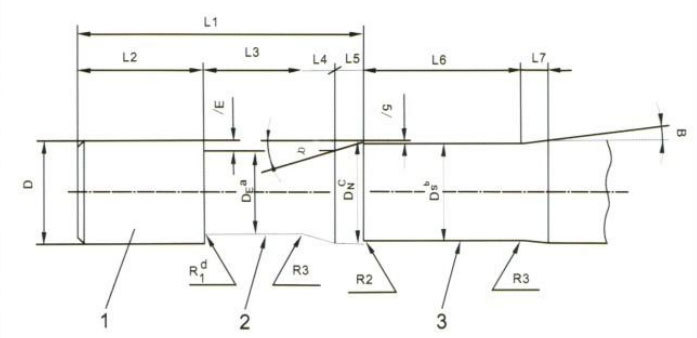

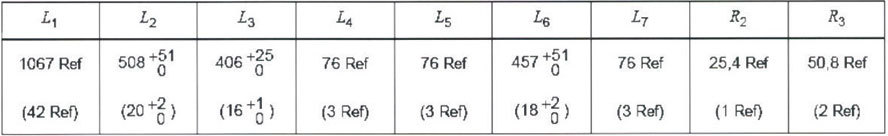

Stress Tress-reliefslot for connection

| Connection |

Internal thread shoulder face to back Notch length of a tooth LX ±1.59 mm |

Cylindrical section of internal thread diameter Dcb +0.40 -0 mm |

Cylindrical section of internal thread After the taper of the taper hole ±20.83 mm/m |

External groove diameter DRC +0 -0.79 mm |

Can replace internal thread shoulder surface To stress dispersion groove length LRG +0 -3.18 mm |

|

NC35 |

82.6 |

82.15 |

166.67 |

82.15 |

85.73 |

|

NC38 |

88.9 |

88.11 |

166.67 |

89.10 |

92.08 |

|

NC40 |

101.6 |

92.87 |

166.67 |

95.81 |

104.78 |

|

NC44 |

101.6 |

101.60 |

166.67 |

106.36 |

104.78 |

|

NC46 |

101.6 |

106.76 |

166.67 |

109.93 |

104.78 |

|

NC50 |

101.6 |

117.48 |

166.67 |

120.45 |

104.78 |

|

NC56 |

114.3 |

121.84 |

250.00 |

134.04 |

117.48 |

|

NC61 |

127.0 |

132.95 |

250.00 |

148.31 |

130.18 |

|

NC70 |

139.7 |

152.00 |

250.00 |

170.54 |

142.88 |

|

NC77 |

152.4 |

166.29 |

250.00 |

188.01 |

155.58 |

|

65/8REG |

114.3 |

134.14 |

166.67 |

137.59 |

117.48 |

|

75/8REG |

120.7 |

148.83 |

250.00 |

161.26 |

123.83 |

|

85/8REG |

123.8 |

172.24 |

250.00 |

185.45 |

127.00 |

Internal thread back hole stress distribution groove/external thread stress distribution groove/Alternate internal thread stress distribution groove

Related Content

Message consultation