Non-magnetic drill collar

The non-magnetic drill collar is made of low-carbon stainless steel independently developed by our company and follows API and SY/T5144 standards. The threads can be processed with cold rolling. Our company can machine double-shoulder threads and other specifications of special threads.

Key words:

Classification:

Message consultation

Previous

Product Details

The Company possesses a complete set of petroleum drilling tool production lines and mainly produces large deep-hole boring machines, ordinary lathes, CNC lathes, mill, printer, etc. The Company has established a dedicated testing center that is equipped with domestic and overseas advanced precision testing equipment and sound testing means to control the whole process of products and strictly abides by API 7-1, API 7-2, SY/T5144 and SY/T5146 standards to ensure that all performance indexes of the Company’s products can meet international standards and standards of American Petroleum Institute (API). The Company has passed IS09001 quality management system certification and HSE management system certification and has obtained the right to use the logos of API petroleum drilling tools. Main drilling tools include non-magnetic drill collar, non-magnetic pressure drill pipe, ordinary drill collar, integrated heavy weight drill pipe, adapter, etc. The annual production capacity is 10,000 pieces. The Company can also machine products according to special requirements of users.

|

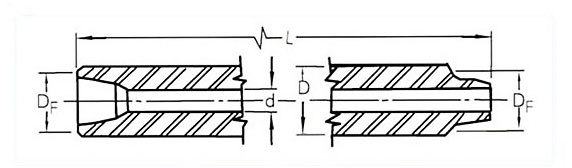

OD |

ID |

mm Length |

Df mm |

Bending strength ration |

|||

|

mm |

in |

mm |

in |

||||

|

NC23-31 |

79.4 |

31/8 |

31.8 |

11/4 |

9150 |

76.2 |

2.57:1 |

|

NC26-35 |

88.9 |

31/2 |

38.1 |

11/2 |

9150 |

82.9 |

2.42:1 |

|

NC31-41 |

104.8 |

41/8 |

50.8 |

2 |

9150 or 9450 |

100.4 |

2.43:1 |

|

NC35-47 |

120.7 |

43/4 |

50.8 |

2 |

9150 or 9450 |

114.7 |

2.58:1 |

|

NC38-50 |

127.0 |

5 |

57.2 |

21/4 |

9150 or 9450 |

121.0 |

2.38:1 |

|

NC44-60 |

152.4 |

6 |

57.2 |

21/4 |

9150 or 9450 |

144.5 |

2.49:1 |

|

NC44-60 |

152.4 |

6 |

71.4 |

213/16 |

9150 or 9450 |

144.5 |

2.84:1 |

|

NC44-62 |

158.8 |

61/4 |

57.2 |

21/4 |

9150 or 9450 |

149.2 |

2.91:1 |

|

NC46-62 |

158.8 |

61/4 |

71.4 |

213/16 |

9150 or 9450 |

150.0 |

2.63:1 |

|

NC46-65 |

165.1 |

61/2 |

57.2 |

21/4 |

9150 or 9450 |

154.8 |

2.76:1 |

|

NC46-65 |

165.1 |

61/2 |

71.4 |

213/16 |

9150 or 9450 |

154.8 |

3.05:1 |

|

NC46-67 |

171.4 |

63/4 |

57.2 |

21/4 |

9150 or 9450 |

159.5 |

3.18:1 |

|

NC50-67 |

171.4 |

63/4 |

71.4 |

213/16 |

9150 or 9450 |

159.5 |

2.37:1 |

|

NC50-70 |

177.8 |

7 |

57.2 |

21/4 |

9150 or 9450 |

164.7 |

2.54:1 |

|

NC50-70 |

177.8 |

7 |

71.4 |

213/16 |

9150 or 9450 |

164.7 |

2.73:1 |

|

NC50-72 |

184.2 |

71/4 |

71.4 |

213/16 |

9150 or 9450 |

169.5 |

3.12:1 |

|

NC56-77 |

196.8 |

73/4 |

71.4 |

213/16 |

9150 or 9450 |

185.3 |

2.70:1 |

|

NC56-80 |

203.2 |

8 |

71.4 |

213/16 |

9150 or 9450 |

190.1 |

3.02:1 |

|

65/8REG |

208.6 |

81/4 |

71.4 |

213/16 |

9150 or 9450 |

195.7 |

2.93:1 |

|

NC61-90 |

228.6 |

9 |

71.4 |

213/16 |

9150 or 9450 |

212.7 |

3.17:1 |

|

75/8REG |

241.3 |

91/2 |

76.2 |

3 |

9150 or 9450 |

223.8 |

2.81:1 |

|

NC70-97 |

247.6 |

93/4 |

76.2 |

3 |

9150 or 9450 |

232.6 |

2.57:1 |

|

NC70-100 |

254.0 |

10 |

76.2 |

3 |

9150 or 9450 |

237.3 |

2.81:1 |

|

85/8REG |

279.4 |

11 |

76.2 |

3 |

9150 or 9450 |

266.7 |

2.84:1 |

● Principal tolerance dimension

|

OD |

OD |

ID |

Length |

Chamfer DF Bendingstrengthratio |

|

|

mm |

in |

||||

|

≤88.9 |

≤31/2 |

+1.20 |

+1.60 |

+152.4 |

±0.4 |

|

>88.9∽114.3 |

>31/2∽41/2 |

+1.60 |

|||

|

>114.3∽139.7 |

>41/2∽51/2 |

+2.00 |

|||

|

>139.7∽165.1 |

>51/2∽61/2 |

+3.20 |

|||

|

>165.1∽215.9 |

>61/2∽81/2 |

+4.00 |

|||

|

>215.9∽241.3 |

>81/2∽91/2 |

+4.80 |

|||

|

>241.3 |

>91/2 |

+6.40 |

|||

● Mechanical property

|

OD |

Yieldstrength |

Tensilestrength |

Elongation |

Shrinkage |

Hardnes |

Impact Akv |

|||

|

mm |

in |

Ksi |

Mpa |

Ksi |

Mpa |

% |

% |

HB |

J |

|

≤180 |

≤7 |

≥120 |

≥828 |

≥135 |

≥931 |

≥25 |

≥50 |

285-360 |

≥75 |

|

>180 |

>7 |

≥110 |

≥759 |

≥130 |

≥897 |

≥25 |

≥50 |

285-360 |

≥75 |

Magnetic property

(Magnetic field=1×105/4π A/m)

1.Relative permeability μr<1.010

2.Magnetic field gradient :ΔB≤0.05μT

Related Content

Message consultation